The Importance of Quality Paperboard Printing & Machinery in Packaging Automation

When we hear the word “automation,” a typical vision comes to mind: warehouses filled with machinery that are powered by sophisticated electronic technology that allow for efficiency, speed, accuracy, and less reliance on human manpower. Yet, have you ever considered the importance of how the quality of printed paperboard and machinery work together to contribute to these efficiencies? For the typical packaging engineer, maintenance manager, and plant manager, they know the ROI for each machine in time, labor, and output, and there is a love/hate relationship when it comes to the quality of printing that goes into packaging that is being fulfilled as it impacts the bottom line directly.

For industries that include, but are not limited to, food, pharmaceuticals, toys, and cosmetics, the success of their packaging, especially folded cartons, is measured closely, and high spoilage levels are frowned upon. As with any manufacturing process, there is a waste factor that is expected for set-up or what is known as “make-ready” costs in the printing industry. Typically 3-5% is factored in for this type of packaging waste which does not account for additional errors that can include, but are not limited to, the printed packaging not being pre-broken, seamed and palleted improperly, or has incorrect coatings which can interrupt automation workflows.

A perfect example of a packaging error is when a carton does not have the correct coating which creates a jam. That jam establishes a disruption in the output levels, drains labor resources, and if perishable items are part of the process, this establishes a need to re-freeze or refrigerate products so they don’t spoil. The challenge here is that typically, when margins get tight, purchasing departments will opt for a less experienced printing vendor or cut corners in the printing process that winds up costing more in the long run. As a result, it is important for the production team to answer the question, “When it comes to printed packaging, how much waste and automation disruption currently exists?” The numbers don’t lie; if the percentage is high or steadily increasing, it is time to make a vendor adjustment, especially in situations where hundreds of thousands of packages are being fulfilled on a daily basis.

It is important to look at the flip side of the equation in regard to quality machinery. In the packaging industry, vendors such as ADCO, who provide clear performance and efficiency guidelines, pride themselves on guaranteeing 98% minimum “uptime” for their machinery. There is a caveat: there are required efficiencies, one of which is the dependency on accurate printing specifications. The industry printing standards include “various coatings, scoring, die cutting, gluing, pre-breaking, weight and density, flatness, or warping, etc.” Another pertinent example is relative to the beauty industry and varnishing techniques. Soft-touch varnish is a finishing that we all know and love – it’s the velvety feeling that you experience on a printed piece, typically on the exterior box. How does this luxuriously printed end product make it through the manufacturing process with minimal scuffs, scrapes, and dents? It all comes down to the combination of the quality of the printing and machinery that can meticulously handle the packaging automation process without further damage.

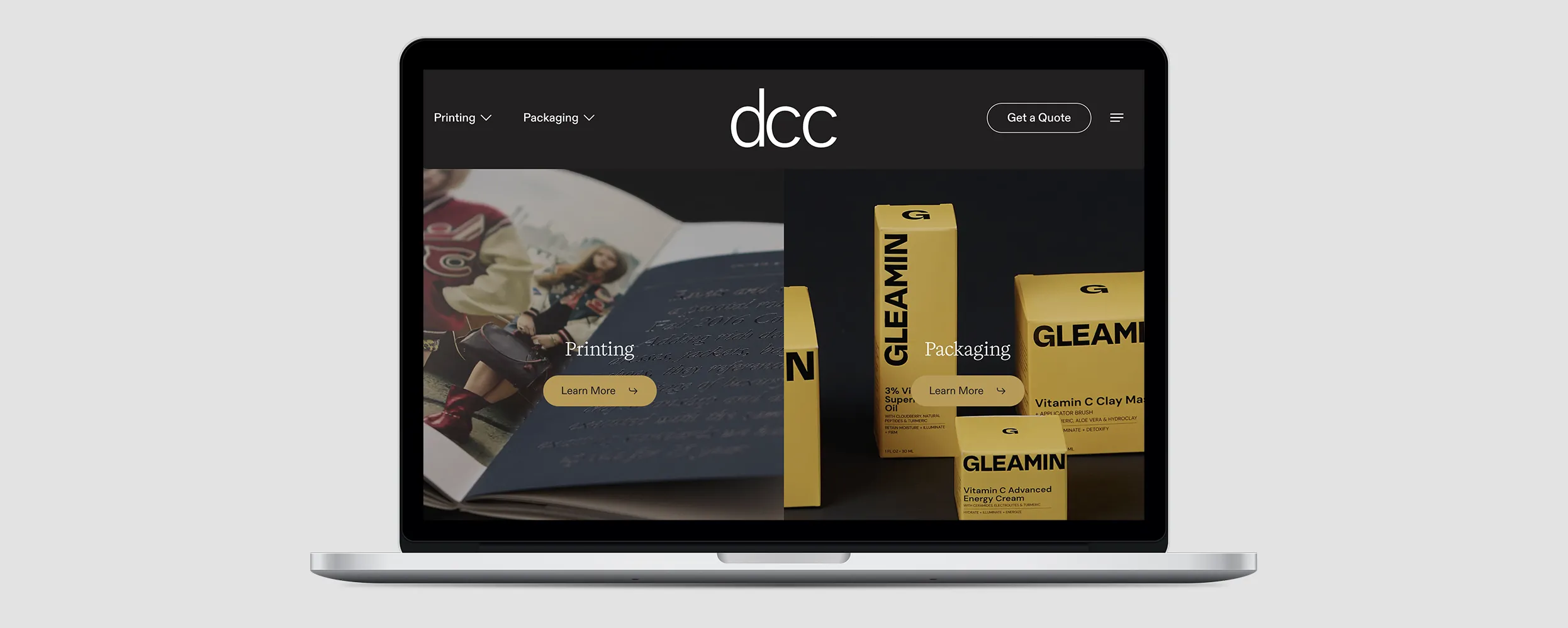

Are you experiencing machinery and printing issues in your packaging fulfillment process? As an ADCO-complaint vendor, a dcc sales representative is available for an onsite visit to review your current automation processes and outline how you can benefit from next-level print production. Remember, we are an Idealliance G7® Master Colorspace Qualified Facility and environmentally-certified provider that delivers excellence in color, short lead times, no minimum quantities, competitive pricing, and on-time delivery to support your bottom line.

Request a review at info@dccnyc.com.