No matter the scale of your project, a lot of time, money, and effort goes into planning and production. Print production is often the final step in bringing your project to life, and it goes without saying that you want to ensure that the print process runs smoothly and that your end product meets all expectations. However, there are several common blunders that can occur leading up to and during print production that can cause issues or delays, even for the most experienced print buyers, and can cost you more time and money than anticipated. With proper preparation and knowledge, these mistakes can easily be avoided. Let’s take a look at some common mistakes and challenges that companies face, along with tips on how to properly specify your next print project and streamline the process so you avoid impacting your bottom line.

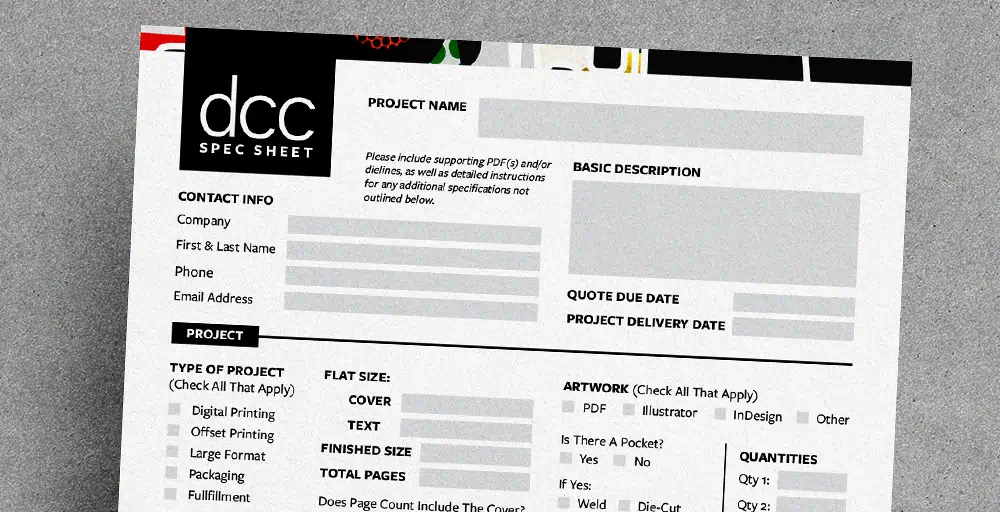

The success of any print job can hinge on proper specifications from the start. That is why it is key to establish clear communication with your printer so you can both ask questions, set clear expectations, and eliminate the guesswork that can result in lost time.

Ro Sandello, dcc Sales Assistant

Challenges

Bidding. Challenges can occur immediately with the bidding process if companies don’t provide accurate or complete information. Oftentimes, companies will reach out to multiple printers to compare costs. Doing so may automate the process. However, facility-specific information might be lost during this process or further ideation and conceptualization could be lacking. Incomplete information provided to the printer can result in a loss of time and money, as well as inaccurate quotes. Knowing up front what your needs are or what questions to ask can help streamline the bidding process and set you up for success.

File Formats. Once a print project is bid and a printer has been procured, one of the most common mistakes that businesses make is not providing their print-ready files in the proper format. Printers typically require files submitted in a specific format. Clear communication with your printer can help determine what they need so you can provide the files accurately the first time. Providing the proper file format with sufficient resolution, proper color model, and correct fonts will help ensure design accuracy and consistency and help avoid issues down the road.

Proofing. Nothing will halt a project faster than identifying a typo or mistake midway through a press run, but believe it or not, not thoroughly proofing content and artwork is a common mistake that print buyers make. Spelling or grammatical errors, alignment issues, errors in image placement, and more, no matter how minor, can greatly impact your final project and cost you money and time if they need to be rectified. That is why it’s imperative to catch all errors prior to your press run and avoid potential issues.

Communication. Just like with any relationship, poor communication can be the downfall of a project and can affect your bottom line. Not being upfront and establishing clear communication with a single point of contact at your printer is another mistake that can lead to ambiguous expectations and cause avoidable issues. Communication is not only key but goes both ways. Printers should be clear with their needs and work with clients to establish clear-cut project goals.

Being aware of these challenges and avoiding common mistakes can help to ensure your project is a success and that the expectations of your business and the printer are met so that no additional time or money is wasted. Proper preparation can ensure that you avoid these pre-press blunders.

Tips for Success

Planning

Plan out your project in advance so that you provide the proper specifications to the printer from the beginning and ensure an accurate quote. Planning in advance will also provide you with ample time to make adjustments if and when issues arise. Some things to consider:

- File format – printers typically require specific formats, such as PDF, that prevent inconsistencies in color and fonts when set up properly. Submitting the wrong file format or low-resolution image files can cause issues with the printing process. It’s always a good idea to provide a PDF file with your specs when requesting a quote to help your printer visualize the project and provide the best recommendations possible.

- Color – knowing upfront how many and what colors your project will need will help your printer determine the best print method and an accurate quote. Are you using PMS colors for consistency? Will your project be full-color? Will there be spot UV? These are all things that will impact how your job is quoted, how you set up your files, and help your printer set you up for success.

- Page Setup – set up your documents with the correct dimensions, image layout, and bleed areas to avoid problems during printing and ensure that your final printed piece aligns with your vision.

- Quantities – when it comes to printing, it’s often the set-up process that adds the most cost to your project. It’s a best practice to order more than you think you’ll need to avoid paying set-up fees again if you need more. Ordering excess will be cheaper in the long run. It’s always a good idea to request a quote for multiple quantities upfront to see the cost breaks.

- Paper – knowing what type of paper is best for your project is crucial to the success of your project. There are so many paper options to choose from, ranging in weight, quality, color, texture, and more. Know what type of paper you envision for your project, and talk to your printer about what will work best. For example, uncoated paper will work best if your final printed piece will be written on. Other things to consider are the type of press, heavy ink coverage, cover pages, and multiple paper weights. If budget is a concern, specify your paper needs and ask for alternatives that will save you money. It’s also recommended to order your paper in advance so it can acclimate before it goes into production.

- Bindery – when it comes to printed pieces like brochures or booklets, providing accurate specifications for folding and binding will ensure a seamless process. Be sure to consider and specify any binding, gluing, scoring, etc., that may be needed. For example, if your project requires a pocket, designate whether it will be welded or glued, or if you are printing a book, what type of binding you want.

- Sustainability – if keeping your project “green” is a requisite, this is important information to discuss with your printer upfront so that they can provide you with FSC, sustainable, or recycled paper options, along with any other green mission practices.

Communication

Establish a relationship with your printer and identify a direct point of contact so that communication between you and your printer is easy and seamless. This will be the key to setting you up for success. Provide the printer with clear project goals and expectations and ask questions to ensure that you provide the printer with all the proper and accurate information to avoid delays, additional costs, and issues down the road. Keep communication clear throughout the print process so you can address issues promptly as they arise.

Pre-Press

You have provided initial specifications to the printer, and they have provided you with quotes, so now it’s time to prepare your project for the press. If your project was specified accurately, you shouldn’t run into any major issues, but there are still things to consider before you go to press.

- Samples – request samples of paper and ink as needed so that there are no surprises down the road.

- Proofs – request that your printer provide proofs before going into final production. This will help flag any missing images, fonts, or layout issues.

- Recommendations – rely on your printer to guide you through the process and be open to suggestions and feedback. Your printer has lots of experience and will know what will work best for your project while still meeting your expectations.

- Press Checks – be on-site for any press checks so that you can review initial sheets and ensure all of the details are correct. Any issues can be addressed and corrected in real time before full quantities are printed.

Hot Tips!

Check out these great tips and tricks from the dcc pros to get you started!

- If producing a saddle stitch book, the total page count should be divisible by 4 (unless you want gate folds!)

- Large format projects should be supplied in CMYK color mode.

- If printing a book that is more than 28 pages on heavy stock, consider wire-o binding vs. perfect binding.

- When printing on uncoated paper, running a UV aqueous coating is recommended.

- Provide a PDF with your specifications to help your printer visualize the project and fill any holes.

- If sustainability is important, specify this upfront.

At dcc, print is what we do, but providing exceptional customer service is at the core of that. It’s always our mission to provide the highest level of customer service to our clients, creating a seamless and easy process and delivering the highest standard of service. Therefore, we make it a priority to over-deliver and exceed our client’s expectations. dcc Senior Account Manager David Nelson says, “We need to meet our customer’s needs, no matter what they are, because the reality is that they can go somewhere else. That is why we make it a priority to manage our clients, provide educated recommendations, and always underpromise and overdeliver.”

We aim to be your partner throughout the print process and our dedicated, hands-on sales team will provide you with recommendations and educate you on the printing process to ensure transparency and avoid any potential issues.